PACC & KERRIDGE

Procedures

The process of steps through the system is guided by the order they are presented on the user menu. Remember that the options you see are controlled by the level of priority you have, and not all of the options discussed will be visible to you.

Create CPD order

This option allows the entry and amendment of an order. Note that the order cannot be amended once the order has been converted (uploaded) to WIP's. Orders which have been uploaded can be identified by the status "W". While it is editable, the order can be changed or modified as necessary. Once it is completed, a quotation can be printed.

The fields on the order header are:

Order No - This is the order reference for the CPD

Dealer Code - This is the code used to identify the customer. Using the code applies the correct pricing for the customer, and also sets the priorities applied for the customer.

Dealer Ref. - This is the customer's order reference number

Create B/O - Set to Y or N to create back-order lines if stock is not available

Fixed - Set to Y or N to fix the price as entered or amended

Order Type - The order type. This defaults values for this customer relating to processing priority and B/O retention. The reserved order type of Q can be used for quotations, and converted later into orders.

Process date - The date the order should be processed. This can differ from the date created if the order is to be processed in the future.

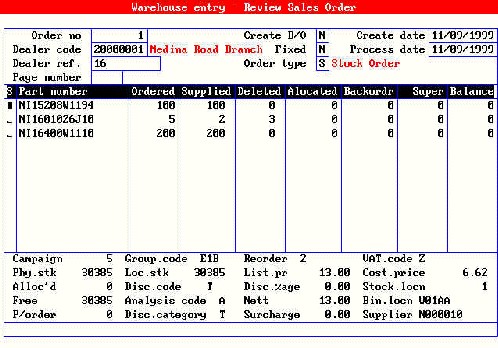

An aditional option to review an order is available. Here, the current state of the order can be viewed. All orders can be reviewed until they are completed.

Upload purchase order

This option is used to upload all of the orders which have been sent to the CPD by the branches, and any orders that have been received and transferred from the Main Dealers and larger brokers by e-mail, modem and diskette.

There are no steps for the user to take other than to select the option. Clearly, this will be done immediately prior to the Allocation run being made.

If there are any items which are not valid for any reason (e.g. Part number not matched with CPD stock file) these are indicated on a report.

Convert purchase order to WIP's

This option is taken to create WIP lines for the parts ordered. After this option is taken, it is not possible to alter the order.

There are no steps for the user to take other than to select the option. Again, this will be done immediately prior to the Allocation run being made.

Allocate stock

This option will take all of the outstanding order lines in the system and allocate the stock from the CPD according to the allocation rules set against the customers and the order types. There is a selection screen which can be used to limit the number of lines selected by type and/or customer.

Review allocations

Using this option, it is possible to look at the results of the allocation run. There is a selection screen which can be used to limit the number of lines displayed by the order type, customer or availability.

Reserve allocations

Once the allocation quantities are deemed to be acceptable, the reserve allocations option is used to reserve the stock against these allocations pending picking of the parts. Until this point, the stock allocated in the allocation run has been available for sale from the standard point-of-sale system.

(Note that any subsequent allocation run would have taken any previous allocations and reservations into account.)

Print picking slips

Here the picking slips can be pinted. The print is for a specific allocation run in full, and the slips are split by customer by order.

Print picking labels

Here picking labels can be pinted. The print is for a specific allocation run in full, and the labels are sequenced by customer by order in the same way as the picking slips.

Amend quantities picked

The quantity actually picked can be amended here if necessary. The final quantity to be supplied can be entered here. Access is via the picking slip reference number

Enter case numbers

Once the goods have been picked, packing case details can be entered here. Access is via the picking slip reference number, and the previous values are retained until changed by the operator. This procedure is not necessary, but if packing details are entered, packing notes can be printed.

Invoice WIP's

Once all of the above procedures have been completed, the goods can be invoiced.

Backorder release

Where a line has been placed on back-order, it can be released against available stock.